aeroarm

The earliest technical drawing I have relating to the aeroarm dates from 1985. One could therefore call it ‘a life’s work’. I consider it the single most important work I have ever accomplished. Not because it is linear, nor uses an air bearing, but because it challenges what we have come to accept concerning analogue disc reproduction. I also consider its design and architecture ground breaking. A ‘product’ this is not.

The aeroarm is a reflection upon the linear cutting process by which all analogue records are made. By creating a mirror-image of that production process, the aeroarm seeks to realise the means of reproduction with as little compromise as is possible, as much fidelity as is possible, and with poetic elegance – for we are sentient beings and such things are of importance to us.

The aeroarm is not for the faint-hearted. It is not a “fit it and forget it” device. It was neither designed as a ‘product’ nor propaganda of promises. It will not buy you time nor ease your life. Indeed, it may drive you crazy… So, what is it?

The aeroarm is a sonic microscope, an instrument for extracting information stored in analogue record grooves. It does this without judgement, simply “doing what it says on the tin” without flattery, prejudice or desire.

The aeroarm is approximately 4.6 times smaller than a conventional tonearm. This means that errors (both in cartridge alignment and inherent to the discs themselves) normally drowned by the sheer mass of a conventional tonearm are magnified by a factor of 4.6 by the aeroarm. Alignment parameters must therefore be set with far greater diligence than normal (forgiveness was never a part of the aeroarm’s brief).

The aeroarm will not work unless it is perfectly horizontal. It will not work if its air supply is contaminated or inadequate. And, as with any other ‘surgical’ instrument, cleanliness is vital: if it is ‘unclean’ in any way, it will clearly tell you so. It must be aligned and operated with understanding, constant care and exactness. However…

This is the ‘fastest’ analogue device I have ever encountered. Being so small, it reacts with astonishing speed to transients (4.6 times faster than normal?) and, having such little mass, doesn’t store energy for later colouration, blurring and sloth.

It seems capable of resolving the finest of details and the fastest of signals. Yet it is, in itself, without signature: one hears no trace of the mechanism, only of the disc in play. It is colourless, has no self ambition nor any desire to “make itself known”. It seeks no glory, offers no pretensions, nor hides from anything. The aeroarm may justifiably be called a “teller of truths”. I seek no more from it than this. This is its justification.

Comparative tonearm geometry: 9" tonearm / 12" tonearm / aeroarm

Effective length: 235 mm / 310 mm / 50 mm

Cartridge offset angle: 24 deg. / 18 deg. / 0 deg.

Overhang: 18 mm / 13 mm / 0 mm

Overall ‘floating’ mass: 280 gr. / 320 gr. / 68 gr.

Effective mass: medium / med-high / low

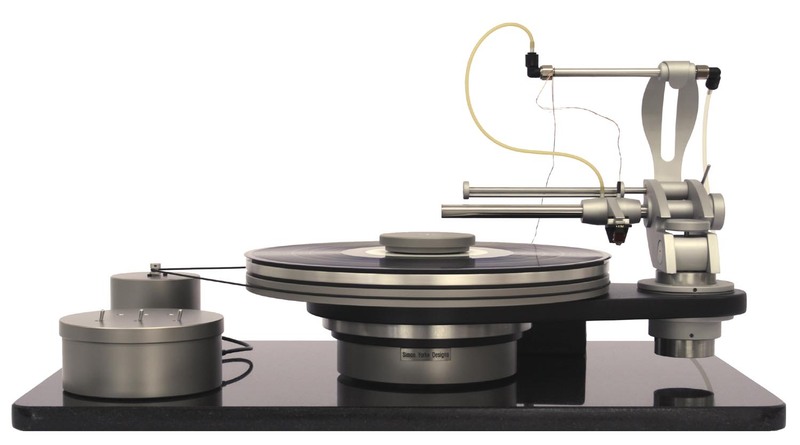

The aeroarm primarily consists of a ‘gantry’ – the main chassis assembly – and a floating ‘carriage’ upon which the cartridge is mounted. The gantry mounts to the record player’s armboard and is adjustable for height and both linear and azimuth alignment parameters. The (detachable) carriage provides facilities for all necessary cartridge alignment parameters such as overhang, offset angle and downforce.

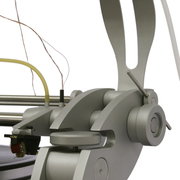

The aeroarm is a low pressure, low volume, high precision aerostatic bearing system. An umbilical cord (air supply tube) provides the air supply directly to the carriage, and a very fine Litz cable allows the cartridge signals to be collected and sourced to a phono preamplifier.

The Litz cable assembly typically supplied is of oxygen-free, high purity copper. We can also offer a cable assembly of high-purity silver for users with all-silver cable connections at increased cost. The cable assembly uses 5 independent strands, permitting true balanced signal transmission to be accomplished. Connections to the cartridge are made by gold-plated lugs, and connection to the audio system via a precision 5-way Lemo connector (to our own connector box and then on, by standard RCA phono cables or XLR types to the audio preamplifier), facilitating the use of more than one carriage/cartridge assembly if required.

An air compressor will be required. We are not authorised to supply air compressors but are able to offer recommendations as to what models are appropriate and how they should be installed and operated. However, we do supply all necessary regulation, filtration, monitoring and air connectors required to enable operation.

The aeroarm typically requires an air supply of approximately 0,5 litres per minute (0,018 c.f.m.) at an operating pressure of 1,5 Bar (22 p.s.i.)

We recommend an air compressor capable of delivering at least double these figures – to provide a good margin of air supply (preferably one with a 4 litre storage tank) – and one which operates as quietly as possible. We advise the air compressor be sited in an adjoining room (never next to the listening position) and connected to a separate spur of the mains voltage supply wherever possible.

As compressed air, even at these low pressures and volumes, may be considered dangerous if used incorrectly, the aeroarm has been designed to protect itself in the event of over-pressure: the supplied regulator limits the output pressure to less than 2 Bar and, for added safety, the air hoses will simply disconnect (blow off) if the air supply pressure exceeds this figure.

The setting of VTA is a highly pertinent issue, given that VTA errors are especially magnified by the short nature of the arm and the observation that no two discs seem to be of exact equal thickness. Height therefore must be independently set for every single disc. For this reason, we have found the use of dial gauges (or their like) to measure and reset absolute height both unhelpful and impractical. As an alternative, we supply a pair of parallel-lined and transparent gauges to enable simple visual alignment of the cartridge each time it is lowered onto a disc.

Whilst the carriage/cartridge assemblies may be interchanged quite rapidly, each exchange will require meticulous realignment of the umbilical cord and signal cable to ensure neither impede free movement of the carriage, so ‘plug and play’ simply isn’t realisable. You have to be a participant if you want to optimise results.

In an ideal world the aeroarm is a near-perfect device and responds according to the basic tenets of thermodynamic theory and Newton’s Laws: correctly installed, a carriage will float perfectly in free space unless an extraneous force acts upon it. When that force is the driving spiral of a record groove we have music. When that force is the impedance (stiffness) of the air supply hose we have an unwanted source of error. Minimising that error is the foremost difficulty associated with the aeroarm as it accounts for probably 80% of its non-linear behaviour. The alignment of the air hose (umbilical cord) is therefore critical to its satisfactory operation and close attention must be paid to it. The stiffness and orientation of the signal cable accounts for the remaining 20% of non-linear mechanical impedance.

We supply a flat and smooth (uncut) disc for the purposes of aligning the air hose. This is very similar to the process required for setting the anti-skating mechanism of a conventional, pivoted tonearm: adjust the bias until the arm is neither drawn to left or right, but will settle wherever it is placed. For a pivoted arm this is achieved by increasing/decreasing the applied bias force. For the aeroarm this is achieved by careful orientation of the air hose in conjunction with precise levelling of the entire record player assembly (using gravity to advantage). So, whilst a linear arm does not require an anti-skating mechanism per se, a ‘bias’ does exist (due to the mechanical impedance of the air hose) and its minimisation must be attended to if optimum results are to be achieved.

Although the aeroarm actually rides warps very well its short nature gives rise to a much larger VTA error in practice and so warp-riding may not be considered its strongest suit. Severe warps are ‘heard’ like non-concentric discs: a rise and fall in pitch.

As the aeroarm gantry is held in a fixed position above the platter surface, adding and removing discs requires a little extra care than normal but is not a major issue (in any event, the record spindle may be simply removed, if preferred) and is quickly assimilated.

The aeroarm was originally designed for archival applications – principally to help in the tracing of large diameter discs revolving at high speeds, where g-forces tend to ‘throw’ a pivoted arm from the disc – but its capacity to resolve the finest of details, and in such a musical manner, has won it many admirers amongst audiophiles and the general music-loving community.

Each unit is supplied with 2 carriages and all the necessary tools and accessories to enable operation (excluding an air compressor) and supplied in a strong package to withstand heavy freight handling and provide secure future storage.

The aeroarm simply gets more out of the record groove than any other arm I have ever encountered, and does this with complete neutrality. Differences between cartridges are precisely heard. Differences between record pressings are precisely heard. In short, everything is clearly heard (including many things you may prefer not to hear: bad recordings, bad pressings, dirty discs, etc.) – and that, ultimately, is what it is for.

The aeroarm is a precision tool, a beautiful object in its own right, a sculpture.

Simon Yorke, June, 2009.